- Place of Origin:

- LD, China (Mainland)

- Brand Name:

- GRT

- Certification:

- CE ,ISO

- Min.Order Quantity:

- 1 Set/Sets

- Price:

- US $19,354 - 29,032/ Set

- Payment Terms:

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- Supply Ability:

- 50 Set/Sets per Month

See More

Shandong Leader Machinery Co.,ltd. have engaged in Oil Refinery Equipment and Microwave Equipment since1997 in China,with 20 years` experience and 80 engineers,, scientific research, manufacturing, installation, commissioning.We can provide customers with design and services of 1-2000 tons oil equipment.factory occupied area is over 100,000 square meters,more than 3200 customers all around the world, we greatly hope to have the opportunity to serve you.

What's more,Shandong Leader Machinery Co.,ltd. is a microwave equipment, microwave drying sterilization machine, microwave heating equipment, microwave drying machine, microwave sterilization equipment, microwave drying equipment, whole grains microwave curing equipment, microwave drying sterilization condiment, Shandong microwave drying Machine, melon seeds microwave dryer and other products specializing in the production and processing company, has a complete and scientific quality management system. Shandong Leader Machinery Co.,ltd.integrity, strength and quality of products recognized by the industry.

Product Description

Continuous industrial cocoa beans multi-layer belt drying machine

Introduction of multi-layer belt drying machine

Materials are uniformly put on the mesh belt dryer machine by the feeder. The mesh-belt uses generally

12-60 mesh stainless steel wire net and it is drawn and moved inside the drier by a transmission device.

The mesh belt dryer machine is composed of several units. For each unit, the hot air is circulated separately.

Some exhausted gas is discharged with a special moisture elimination blower.The waste gas is controlled through an

adjustment valve. The hot air passes through the mesh belt covered with the material from the top to the bottom or from

the bottom to the top and this will complete the heat and mass transfer process.This process will bring material water

away. The meshbelt moves slowly, Running speed can be freely adjusted according to material temperature.

The final products after mesh belt dryer machine will fall into the material collector continuously. the top and low circulation

layer can be freely equipped according to the users’ demand. The layer number can be selected according to the demand.

Application of multi-layer belt drying machine

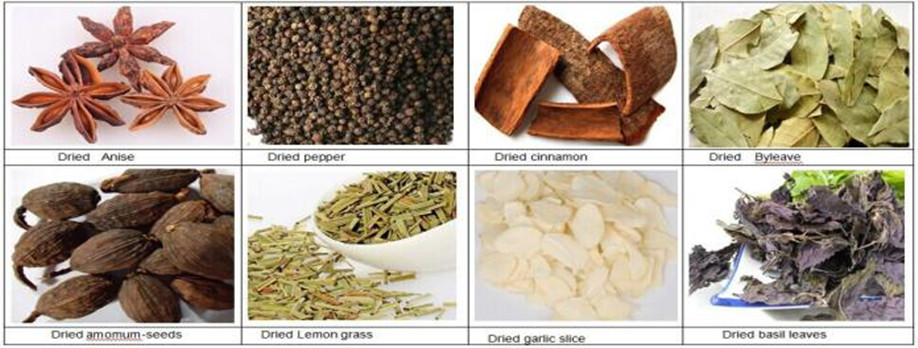

Widely used in metallurgy, building materials, ceramics, organic fertilizer, chemical foodstuff, fruit and walnut kernels,

pharmacy, construction material, and electronic industry, and particularly it is adapt to dry the raw materials which have good air

permeability and shaped in sheet, strip or granule.

Features of multi-layer belt drying machine

1. Hot air go through material layer from bottom to top and from top to bottom, it increases the contact area of material

and hot air and also the drying intensity.

2. We adopt unique internal air blowing device. It not only increases the relative speed of material and hot air and drying

intensity but also the uniform drying of materials.

3. It is fully enclosed structure. There is no outer air pipes except the dehumidifying air pipe, thus the materials won’t be polluted and the heat efficiency and working condition are improved.

4. It is easy to contact with all parts inside the main machine, so it's easy for cleaning.

5. The belt speed can be controlled easily to guarantee the final moisture of products.

6. Easy to assemble, after assembling the conveyor hoister the machines can be working.

Specification

|

model

|

GRT-1.2A |

GRT-1.2B |

GRT-1.6A |

GRT-1.6B |

GRT-2A |

GRT-2B |

number of layers |

4 |

5 |

4 |

5 |

4 |

5 |

bandwidth |

1.2 |

1.2 |

1.6 |

1.6 |

2 |

2 |

|

segment length (m) |

8 |

10 |

8 |

10 |

8 |

10 |

|

material Spread thickness (mm) |

10~80 |

|||||

|

Operating temperature (℃) |

60~150 |

|||||

steam pressure (Mpa) |

0.2~0.8 |

|||||

|

steam consumption (kg/h) |

120~300 |

150~375 |

150~375 |

170~470 |

180~500 |

225~600 |

|

Drying time (h) |

0.2~1.2 |

0.25~1.5 |

0.2~1.2 |

0.25~1.5 |

0.2~1.2 |

0.25~1.5 |

drying intensity (kgH20/h) |

60~160 |

80~220 |

75~220 |

95~250 |

100~260 |

120~300 |

Fan total power (kw) |

6.6 |

8.8 |

9 |

12 |

12 |

16 |

|

Total power (kw) |

7.15 |

9.55 |

9.55 |

12.75 |

12.55 |

16.75 |

Continuous industrial cocoa beans multi-layer belt drying machine ,granular, sheet-like or gel-like food ,and additive, flavoring, medicine, raw material of herbal medicine, nutritional health products, agriculture & sideline products, non-fried(or oil-saving)instant noodles, noodles, rice powder noodles, soy products, beef jerky, preserved meat, dried fish ,tea, tobacco and so on; and for drying, peeling and baking almond, peach kernel, groundnut kernels, chestnut and so on; and for puffing of leisure food ,pachyrhizus chips, potato chips, dried shrimps,Shandong Leader Machinery Co.,ltd. fish maw and so on; and for sterilizing and oral liquor, pickles, a variety of small packaging food ;and for drying beans; and for thawing the frozen fish ,poultry; and for drying and desulfurating and deoxidizing the metallurgical chemical products; and for drying printing and dyeing products, ceramics, glass, chemical fiber, cotton yarn, wood, leather, bamboo products, insulation materials, building materials, cork, alveolate cardboard, corrugated ,and so on.

AAA1

Continuous industrial cocoa beans multi-layer belt drying machine is electromagnetic waves which frequency from 300 MHZ to 300000 MHZ. Water molecule of heating medium material is polar molecule, its polarity orientation of the electric field with changes caused by the movement of molecules under high rapid frequency electromagnetic field changes, cause the numerator movement and the friction effect of each othe. Microwave field can field at this time into medium heat, make temperature of material increase, produce and popped a series of materialization process to reach the purpose of microwave heating dry.

Microwave heating features:

AAA2

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

LD Miss Candy

Skype: leaderfoodmachine9

Mobile: +86 18363700691 (Also WhatsApp & Wechat)

Email: sales9@ldfoodmachine.com

Crispy Rice Food Processing Line