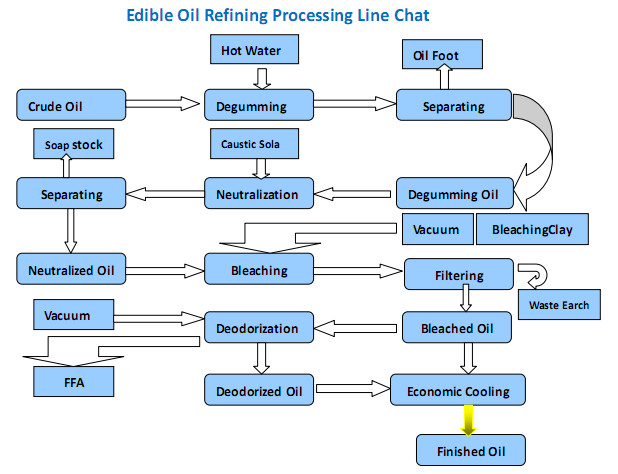

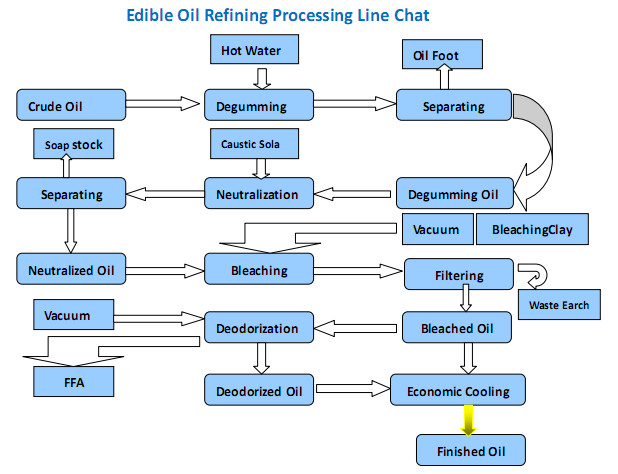

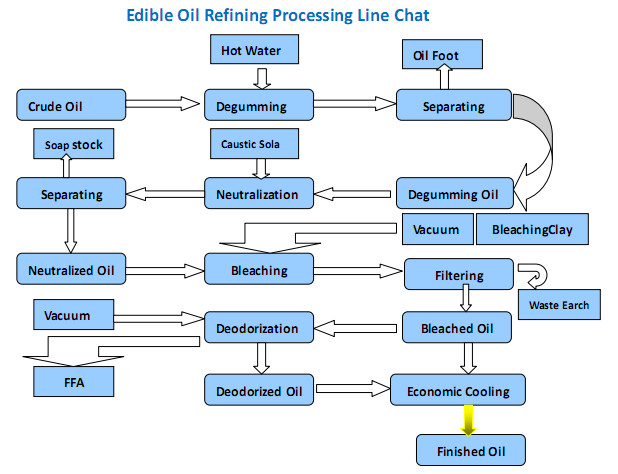

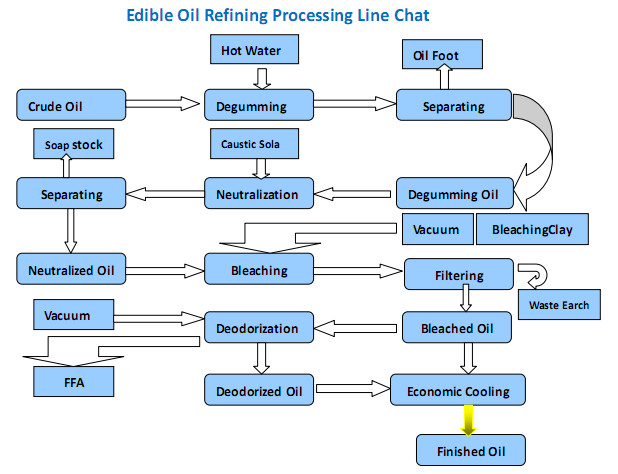

According to the difference of alkali thickness and oil temperature for 1-20TPD Small Scale Oil Refining Line, the process of dealkalizing of Mini crude cottonseed oil cake oil refinery machine plant for sale is divided into two types, one is low temperature with thick alkali (its initial temperature is 20 ~ 30 ℃, alkali thickness is 20 ~ 30 Be) and another one is high temperature with light alkali (its initial temperature is 75 ℃, alkali thickness is 10 to 16 Be). The former of Mini crude cottonseed oil cake oil refinery machine plant for sale is generally applied and the latter of Mini crude cottonseed oil cake oil refinery machine plant for sale is mainly used for crude oil which has low acid value, light clour and lustre, and less impurity.

Specifications of 1-20TPD Small Scale Oil Refining Line:

1. soy lecithin

2. suite for soybean, corn germ, peanut, sesame, rapeseed, rice bran, cottonseed, tea seed, sunflower seed oil press

3. pure oil, edible oil quality

4. various capacity:10t/d, 20t/d, 30t/d, 40t/d, 50t/d, 60t/d, 70t/d, 80t/d,100t/d, 150t/d

5. used for hot and cold press

Product Description of 1-20TPD Small Scale Oil Refining Line:

1. What is the Mini crude cottonseed oil cake oil refinery machine plant for sale?

Raw material→Materials dosing →Magnetic separation→Cleaning→crusher→flaker→ Extrusion Puffing →Counter-current drying→To leaching plant

2. What is 1-20TPD Small Scale Oil Refining Line?

Material embryos→Extraction→Wet meal→Evaporation→Cooling→Product meal packing

↓

Mixed oil→Filter→Negative pressure evaporation → Crude oil→Solvent recovery

Shipping of Mini crude cottonseed oil cake oil refinery machine plant for sale:

1. FedEx/DHL/UPS/TNT for samples, Door-to-Door,

2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving,

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

Payment Terms of Mini crude cottonseed oil cake oil refinery machine plant for sale:

1. Payment: T/T, Western Union, MoneyGram,PayPal; 30% deposits; 70% balance before delivery,

2. MOQ: 1pcs,

3. Warranty : 3 year

Product Description

Crude cottonseed oil refinery plant for sale

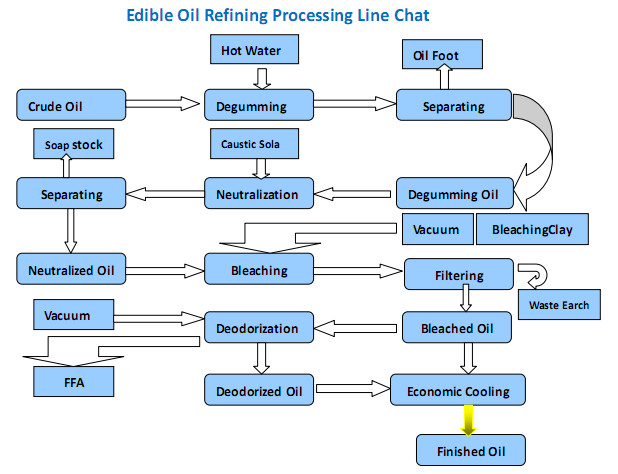

There are two kinds of processes:

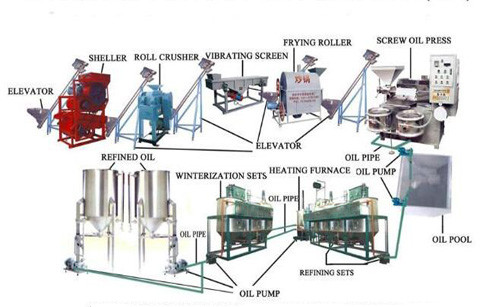

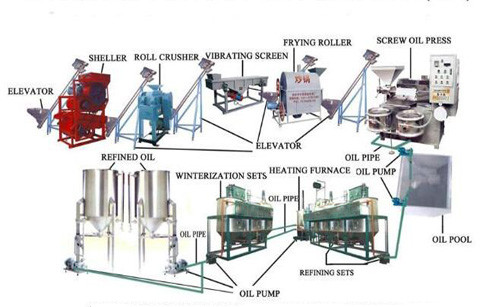

Option 1: Dehulling, Kernel and Hull Separation, Flaking, Cooking, Pressing, Oil Residue Separation.

Option 2: Dehulling, Kernel and Hull Separation, Softening, Flaking, Cooking, Expanding, Cooling.

Cottonseed oil mill plant with capacity 10-200TPD basis on Turn key project

Related Keywords :Cottonseed Pressing turnkey project China equipment manufacturer factory engineering supplier

Process Description of Cottonseed oil mill plant:

The purpose of preparation is to extract a portion of oil by mechanical pressing while providing pressing cakes for extraction plant. It is a succession of several of the following processes: Bran Cleaning & Weighing, Cracking, Softening, Flaking, Pressing, Oil Residue Separation.

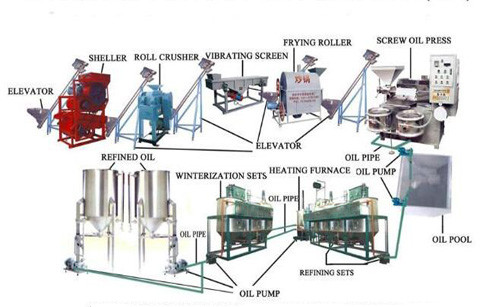

Description of Process of Cottonseed oil mill plant:1. Dehulling Section

Frequently-used equipment tooth type dehuller is designed to crack cottonseed hull and separate kernel through double rolls with speed difference.

2. Kernel and Hull Separation Section

Screening and aspirating are combined to separate hull and kernel from dehuller. Frequently-used equipment are step screener, round screener, separating screener.

3. Softening Section

Horizontal drum softener is designed to adjust temperature and moisture of cottonseeds kernel previous to flaking, improving oil yield greatly.

4. Flaking Section

The purpose of flaking is to turn the broken cottonseeds into thin flakes (from 0.3 to 0.35mm) for the subsequent oil extraction through mechanical pressing. In addition, flakes thickness can be adjusted through roll pressure adjustment device.

5. Pressing Section

Cottonseed is a kind of high oil-containing oilseed. Generally it is necessary to extract a portion of oil by mechanical pressing previous to subsequent process. Expeller with auxiliary cooker ensures material reach proper temperature and moisture. Pressing cakes containing residual oil from 14% to 18% is then treated by solvent extraction while crude oil is to be filtered.

The temperature of the soybeans after expanding is above 100â,the moisture is over 12%,Because the solvent is easy to evaporate, we need to cool the materials before extraction.

6. Expanding Section

The purpose of hull crushing is to change the physical features of the hull,make it is easier in the downstream processing such as pelleting.The shape of the hull is supposed to be the same as the meal,so that we can add the hull into the meal for the purpose of adjust the proportion of protein.

7. Oil Residue Separation Section

Due to high content of residue in crude oil, it is necessary to separate oil residue by oil drag conveyor firstly, crude oil then enters to settling tank for further separation. Collected residue is returned to pressing section while crude oil from settling tank is pumped to frame filter or leaf filter for further removing impurities.

8. Expanded Material/Pressed Cakes Cooling Section

Cooling drag conveyor is designed to cool down expanded material/ pressed cakes with high efficiency, then cakes is conveyed to extraction plant.

Main Features of Cottonseed oil mill plant

1.Absorbing the worldâs leading core extraction technology, design and develop a process which is efficient, economical and reliable. Adopting box-chained loop type extractor can effectively achieve low residual oil, low solvent consumption and low failure rate of equipment. Thus, customers will have little cost and investment, and profit maximization will be achieved.

2.Full automatic computer control system is adopted in extracting process, adjust automatically and operate stably.

3.Negative pressure technology is adopted in condensate system. Using the secondary steam which comes from the DTDC as the heat source of first evaporation, thus can maximum save the energy consumption.

4.Stainless steel heat exchange tubes and multi-stage baffling make the condenser have a high heat transfer efficiency, also the water consumption is low.

5.Composed of pre-extraction, extraction and draining sections. There is material turnover in the process of extraction to make the extraction uniform and thorough. Special self-cell solvent spraying ensures the best effect during extraction.

Related Projects overseas of Cottonseed oil mill plant:

| Country

|

Related Oil/Fat Project List of Overseas

|

Raw material

|

| Bangladesh |

30T/D rice bran expanding and extraction |

Rice bran |

| Bangladesh |

5T/D rice bran oil refining project |

Rice bran |

| Malaysia |

100T/D palm fruit oil refinery project |

Palm fruit |

| Sudan |

30T/D The whole production line for Peanut |

Peanuts |

| Bolivia |

60T/D soybean oil refinery project |

Soybean |

| Indonesia |

30T/D copra oil extraction , and 20T/D copra oil refinery |

Copra |

| Kazakhstan |

3T/D cotten seeds oil refinery project |

Cotten seeds |

Certifications

Detailed Images

Machine Parts

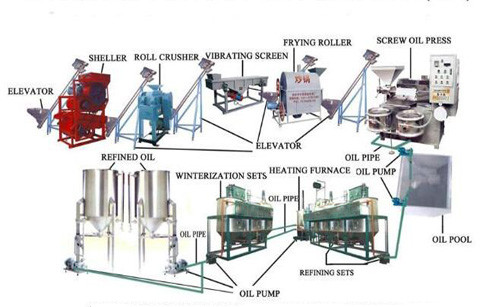

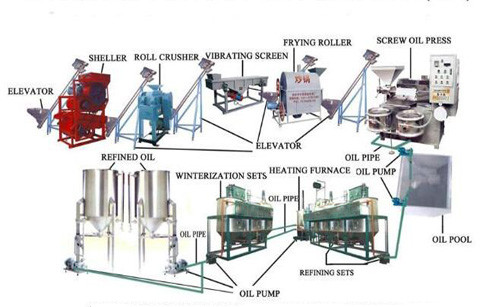

Name: Oil Pressing Machine

Brand: Beiside

Original: China

A Screw consists basically of a worm assembly,a shft fitted with spirally-arranged worm sections,rather like a screw.The shaft turns horizontally in a cage consisting of barrel bars that are clamped together forming a kind of sloted tube around the shaft.

Main Features

Name: Solvant Extraction Plant

Brand: Beiside

Original: China

In turning,the worm assembly moves the oil-seed from the feed-end to the dischage-end,expelling the oil through the slots between the bars of the of the cage.The oil-seed,as it moves along the shaft,loses oil,and its volume decreases accordingly.

Machine Parts

Name: Screw Oil Presser with Three Level Cooker

Brand: Beiside

Original: China

The design of the press must allow for this change of volume,and the friction betweent the cake and the cage must be maintained high enough to prevent the cake from rotating.The cake is expelled from the press through a choke gear,an adjustable cone forming an annular opening of variable size.

Main Features

Name:Oil Extraction Plant

Brand: Beiside

Original: China

The choke gear can regulate the resistance of the cake to the movement of the screw,and the pressure exercised on the cake.To maintain this pressure essential for expelling the oil,a positive feed system is required.

The feed system is frequently a worm conveyor,either vertical or horizontal,that presses the oil-seed into the screw-press at the feed-end.

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing & Delivery

| Packaging

|

| Size |

123 (L) * 456 (W) * 789 (D) |

| Weight |

1.2 T |

Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

| Packaging

|

| Size |

123 (L) * 456 (W) * 789 (D) |

| Weight |

1.2 T |

Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

Related Products

Automatic Hydraulic Oil Presser

91.8% Response Rate

Screw Oil Presser with Filter

91.8% Response Rate

Spiral Oil Presser

91.8% Response Rate

Shandong Leader Machinery Co.,Ltd. value "honesty, innovative and quality" because Shandong Leader Machinery Co.,Ltd. know that Shandong Leader Machinery Co.,Ltd. are not only supplying equipment to our clients but the partners to help our clients to get a better result.Keeping this in our mind,Shandong Leader Machinery Co.,Ltd. not only make high quality food processing equipment, but also help the clients to figure out the optimum processing work flows,make amendments according to client's specific needs,training staffs for the user of our equipment and even more, because Shandong Leader Machinery Co.,Ltd. believe that our users or clients' success is the foundation of ours.

Shandong Leader Machinery Co.,Ltd. is one of the leading Manufacturers and Suppliers of Mini crude cottonseed oil cake oil refinery machine plant for sale.Shandong Leader Machinery Co.,Ltd. manufacture Mini crude cottonseed oil cake oil refinery machine plant for sale making machine using cutting-edge technology, Shandong Leader Machinery Co.,Ltd. have many kinds of 1-20TPD Small Scale Oil Refining Line for you reference,such as Mini crude cottonseed oil cake oil refinery machine plant for sale ,Shandong Leader Machinery Co.,Ltd. can meet your different requirement in 1-20TPD Small Scale Oil Refining Line.Welcome to contact Shandong Leader Machinery Co.,Ltd.,contact name:Ms.Myra for a quotation

(Tel/whatsapp:0086-18363092712, Email:sales2@ldfoodmachine.com,Skype:leaderfoodmachine2).Welcome to send us your enquiry about capacity for Mini crude cottonseed oil cake oil refinery machine plant for sale, inform us raw material you want to use for Mini crude cottonseed oil cake oil refinery machine plant for sale,and specific requirements for Mini crude cottonseed oil cake oil refinery machine plant for sale.Shandong Leader Machinery Co.,Ltd. will provide you best solution for your project about 1-20TPD Small Scale Oil Refining Line.