- 86-05331-85064683|

- Request a quote

See More

With the development of social economy and urbanization, the discharge of urban and industrial wastewater in China has increased year by year. By 2005, the total discharge of industrial and domestic wastewater has risen to 52.45 billion tons, of which 21.11 billion tons are industrial wastewater and 26.13 billion tons are domestic wastewater, an increase of 14.2% compared with 2003. At the same time, sewage treatment facilities are also increasing. In 2005, 69,231 sewage treatment facilities were set up in China, an increase of 6.3% over 2003.

Microwave drying machinery and equipment

In 2005, the treatment rate of municipal wastewater was 39.4%, and the treatment rate of municipal industrial wastewater was 99.4%. If 10 tons of dewatered sludge were produced per 10,000 tons of wastewater, the discharge of dewatered sludge in 2005 reached 32.27 million tons, and increased year by year.

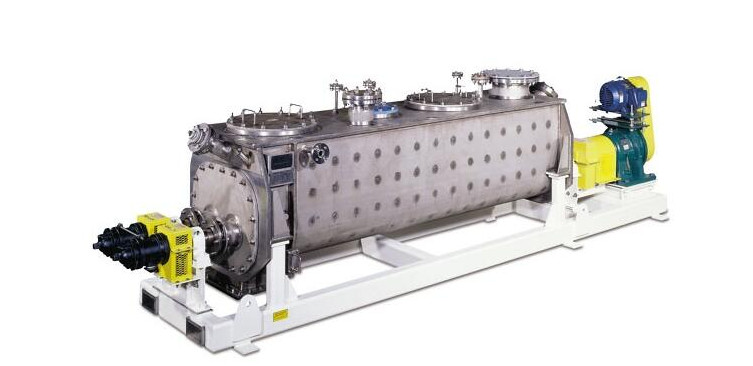

Thermal drying of sludge is an effective method for sludge reduction and resource utilization. There are various methods, including direct contact drying and indirect contact drying. The indirect contact drying method has attracted more and more attention due to its high thermal efficiency and low exhaust emissions. The pulp-leaf dryer is an effective indirect contact drying equipment. The drying characteristics of sludge in the pulp-leaf dryer are studied in this paper.

Sludge drying system consists of paddle-type sludge dryer, heat-conducting oil furnace, oil pump, motor and electric control cabinet. The drying area of paddle-type dryer is 2 m 2. The heat conducting oil used as heat transfer medium is heated by resistance wire. The heat transfer mechanism consists of a pair of hollow hot shafts and a heat jacket of the body of the heating dryer. The wet sludge is entered by the inlet port. In dryer, the hollow hot axle drives the stirring of sludge by motor, and the heat conducting oil transfers heat to the wet sludge through the hollow hot axle and jacket.

Water in sludge is mainly composed of free water, interstitial water, capillary water, surface bound water and molecular bound water. Free water has been removed during the mechanical dewatering stage. Therefore, the thermal drying characteristics of sludge mainly reflect the dewatering characteristics of interstitial water and bound water under heating conditions. Firstly, the weight loss curves of single sludge particles were studied. The dewatered sludge was made into a sphere with diameter of 2 cm. The weight loss curves at different temperatures were observed by thermogravimeter, as shown in Figure 3. With the increase of temperature, the weight loss time of sludge was shortened obviously. The weight loss time of sludge particles was 8 500 s at 150 C, 5 000 s at 200 C, and the drying time was reduced by 41.2%.

In the initial stage, the sludge particle temperature rises from the ambient temperature to the furnace temperature after entering the weightlessness meter, so the weight loss rate increases gradually. After that, the weight loss rate of sludge decreases almost in a straight line, which mainly depends on two factors. Firstly, because the water near the outer surface of the granule is removed first in the process of weight loss, when the drying interface shrinks to the inside of the granule, the diffusion resistance of water separation increases continuously; secondly, the combination of interstitial water and capillary water feeds the sludge continuously from the left inlet of the blade dryer, and the two ends of the dryer. The hot axle rotates slowly under the drive of the speed regulating motor and stirs the sludge continuously and uninterruptedly. At the same time, the sludge moves slowly in the dryer under the drive of the blade. The sludge is dried by stirring while using the blade dryer. The heating surface of the sludge changes constantly, and the sludge is heated more uniformly.

By agitating the blades of the propeller, the sludge effectively overcomes the inhibition of the first factor on the weight loss rate.

At the same temperature of heat conducting oil, the moisture content of sludge changes along the drying machine body at different rotational speeds of hot axes. When the rotational speed of hot axes is doubled, the moisture content of sludge outlet rises from 42% to 60%. It can be seen that the rotational speed of hot axes has a great influence on the moisture content of sludge outlet of dryer, which is due to the energy source of impeller blades in the process of sludge drying. Environment 2007, Phase 3-55-swinging stirring, heat transfer and promotion three major functions, and the speed of the hot shaft and blade to promote the role of sludge is proportional, after the increase of the speed of the hot shaft, sludge in the dryer to speed up, resulting in shorter residence time in the dryer, increased water content at the outlet.

See the news list>>