What is the main material of Biodiesel Oil Production Line?

NO. Raw material Note

1 Slaughterhouse scraps From slaughter house

2 swill cooking oil, swill Waste cooking oil

3 Fatty Acid & Acid Oil from plant refinery For example the bean & peanut etc.....

4 Animal bone, viscera fatty and so on......

The palm oil press mills in malaysia is same,just processing and catalyst is different,Shandong Leader Machinery Co.,Ltd. engineer will training you as your raw material use.

What is the advantages of biodiesel?

Engine is starting at low temperature(-10C).

It not belongs to dangerous cargo,so it’s easy to transport.

There is less sulfur and aromatic alkyl in biodiesel,so it's less harmful to human and environment.As a kind of renewable energy sources,the biodiesel will not finised.

The supply of biodiesel is not controlled by OPEC,it’s benefit to the stability of international petroleum market.

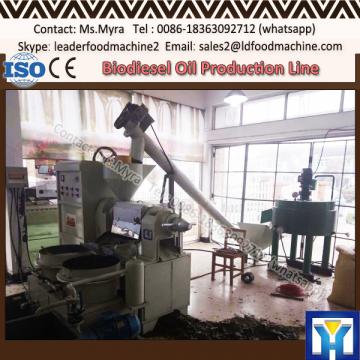

Oil press project

palm oil press mills in malaysia

After the pressing of the palm oil through the oil press machine, the liquid oil and the fibrous cake containing a small amount of oil are obtained. The fiber cake is subjected to further processing to obtain the palm nuts doping in it. When the fiber cake falls into the cake After the dragon, the oil press through the intermittent leaves of the dragon, will first ask the cake to break up.

During the forward transport process the cake vapor is continuously evaporated, dried, and finally falls into the fiber, the nuclear separator, this step is used to separate the fiber and palm kernel. By the centrifugal fan and the wind network composed of suction system, the fiber wind transported to the boiler room for combustion.

The larger proportion of the brown nucleus from the fiber, another part of the nuclear separation machine into the bucket elevator, the wind selected nuclei need to remove the stones, iron and branches. After the clean fruit will be transported to the nuclear seed cans in the tank can be carried out on the wetting of the wet nucleus further dry.

Product Description

Complete Process of palm oil press mills in malaysia

Specificaitons of cooking oil production equipment

1.Drying:Adjust moisture of rice bran to meet the requirement of going to extraction process.

2.Cooking process: use steam cooking, inject direct steam and cook the flakes to meet the requirement of oil press.

3. Pre-press: Press the flakes to leave about 16%-18% in the cake. The cake will go to extraction process.

4.Filteration: using vibration filter to filter the crude oil to remove the impurities.Detailed Images

Our company

Shandong LD Grain And Oil Machinery Co., Ltd. founded in 1976, with nearly 40 years of development and growth, in 2002 passed the ISO9001 quality management system certification, National Food Processing Equipment Engineering Technology Research Center, the National agro-processing technology and equipment research and development sub-centers and the provincial post-doctoral research base development platform.

Certificate of cooking oil production equipmentï¼

Our Service

We will be commitment to provide high quality products with perfect site services and after-sales service. Now the specific commitments are as follows:

1. Ensure to timely provide complete sets of equipment and accessories.

2. Ensure that one-time installation debugging acceptance.

3. Priority to provide customer our new craftworks and products.

4. Free training technological operator to ensure the trained staff can operation independently.

5. In the installation process,we will appoint a installation supervision staff on the spot.

6. we will offer an experienced project manager, organize a good installation team for the work of field installation debugging.

7. In the warranty period, all because of the quality of products has caused the damage or failure of equipment,

8. After the receipt of customers notice,we will suggests the method to solve problem within six hours,or send specialist to the site to solve the problem within twenty four hours.

FAQï¼

Contact us

How to contact us?

Please Send Your Inquiry Details in the Below for Free Sample, Click "send" Now!thanks.

Shandong Leader Machinery Co.,Ltd. is one of the leading Manufacturers and Suppliers of palm oil press mills in malaysia.Shandong Leader Machinery Co.,Ltd. manufacture palm oil press mills in malaysia making machine using cutting-edge technology, Shandong Leader Machinery Co.,Ltd. have many kinds of Biodiesel Oil Production Line for you reference,such as palm oil press mills in malaysia ,Shandong Leader Machinery Co.,Ltd. can meet your different requirement in Biodiesel Oil Production Line.Welcome to contact Shandong Leader Machinery Co.,Ltd.,contact name:Ms.Myra for a quotation

(Tel/whatsapp:0086-18363092712, Email:sales2@ldfoodmachine.com,Skype:leaderfoodmachine2).Welcome to send us your enquiry about capacity for palm oil press mills in malaysia, inform us raw material you want to use for palm oil press mills in malaysia,and specific requirements for palm oil press mills in malaysia.Shandong Leader Machinery Co.,Ltd. will provide you best solution for your project about Biodiesel Oil Production Line.

Shandong Leader Machinery Co.,Ltd. value "honesty, innovative and quality" because Shandong Leader Machinery Co.,Ltd. know that Shandong Leader Machinery Co.,Ltd. are not only supplying equipment to our clients but the partners to help our clients to get a better result.Keeping this in our mind,Shandong Leader Machinery Co.,Ltd. not only make high quality food processing equipment, but also help the clients to figure out the optimum processing work flows,make amendments according to client's specific needs,training staffs for the user of our equipment and even more, because Shandong Leader Machinery Co.,Ltd. believe that our users or clients' success is the foundation of ours.

Product Description

Product Description

Our company

Our company