small wheat flour mill/corn mill/wheat flour mill

Introduction of small wheat flour mill

The roller mill is the main equipment for milling section in flour mills. It mainly depends on a pair of differential transmission and relative rotation rolls to break wheat, meanwhile, scrapes endosperm from wheat bran, then endosperm grinding into flour. The material can be extruded, sheared and broken during the equipment working and so as to achieve a certain grinding effect, each roller mill has two independent drive, feeding, and grinding systems and play their functions in the flour passages.

Features of small wheat flour mill

1) Full pneumatic control, the machine can be controlled independently or be controlled concentrated through a remote panel;

2) Rolls adopt the eccentric lever clutch structure, roll groups undertake running reaction by themselves;

3) Rolls lay out horizontally, the material is easy to grinding area, and rolls are easier assembly, disassembly and maintenance;

4) The fast and slow grinding rolls are driven by triple-wheel teeth wedge belts with advantages of no jump teeth, no deflection, smooth operation, and low noise;

5) The upper and lower split structure is designed for the two side frames of roll mill; the damping washer is fitted in the upper and lower joint;

6) The negative air flow pressure device is adopted in the reduction system to improve feeding condition, reduce the temperature of rolls and materials;

7) Pneumatic-controlling elements, the bearing of rolls, teeth wedge belts are the top ranking products of the world;

8) The completely enclosed and duplex structures are adopted for the machine, the static electric sprayed paint technology is used in surface treatment.

Technical Parameter 1 (ø250)

Item |

Unit |

Specification |

Model |

|

ASL- 25/125 |

ASL-25/100 |

ASL-25/80 |

ASL-25/60 |

Roll Diameter×Length |

mm |

ø 250×1250 |

ø 250×1000 |

ø 250×800 |

ø 250×600 |

Diameter Range of Roll |

mm |

ø 250- ø 230 |

Fast Roll Speed |

r/min |

450-600 Can Be Customized |

Gear Ratio |

|

1.25:1 1.5:1 2:1 2.5:1 |

Feed Roll Ratio |

|

2:1 1.4:1 1:1 |

Power |

KW |

30-5.5 |

Main Driving Wheel |

Diameter |

mm |

ø 345 |

Groove |

|

15N(5v) 4 Grooves 6 Grooves |

Working Pressure |

Pa |

6×105 |

Dimension (L×W×H) |

mm |

2060×1490

×1895 |

1810×1490

×1895 |

1610×1490

×1895 |

1410×1490

×1895 |

Gross Weight |

kg |

4100 |

3300 |

3000 |

2700 |

Technical Parameter 2 (ø300)

Item |

Unit |

Specification |

Model |

|

ASL-30/125 |

ASL-30/100 |

|

Roll Diameter×Length Diameter×Length |

mm |

ø 300×1250 |

ø 300×1000 |

|

Diameter Range of Roll |

mm |

ø 300-ø 270 |

|

Fast Roll Speed |

r/min |

450-600(Can Be Customized) |

|

Gear Ratio |

|

1.25:1 1.5:1 2:1 2.5:1 |

|

Feed Roll Ratio |

|

2:1 1.4:1 1:1 |

|

Power |

KW |

45 — 7.5 |

|

Main Driving Wheel |

Diameter |

mm |

360 |

|

Groove |

|

15N(5V) 6 Grooves |

Working Pressure |

Pa |

6×105 |

|

Dimension (L×W×H) |

mm |

2060×1690×1930 |

1810×1690×1930 |

|

Gross Weight |

kg |

4600 |

4000 |

|

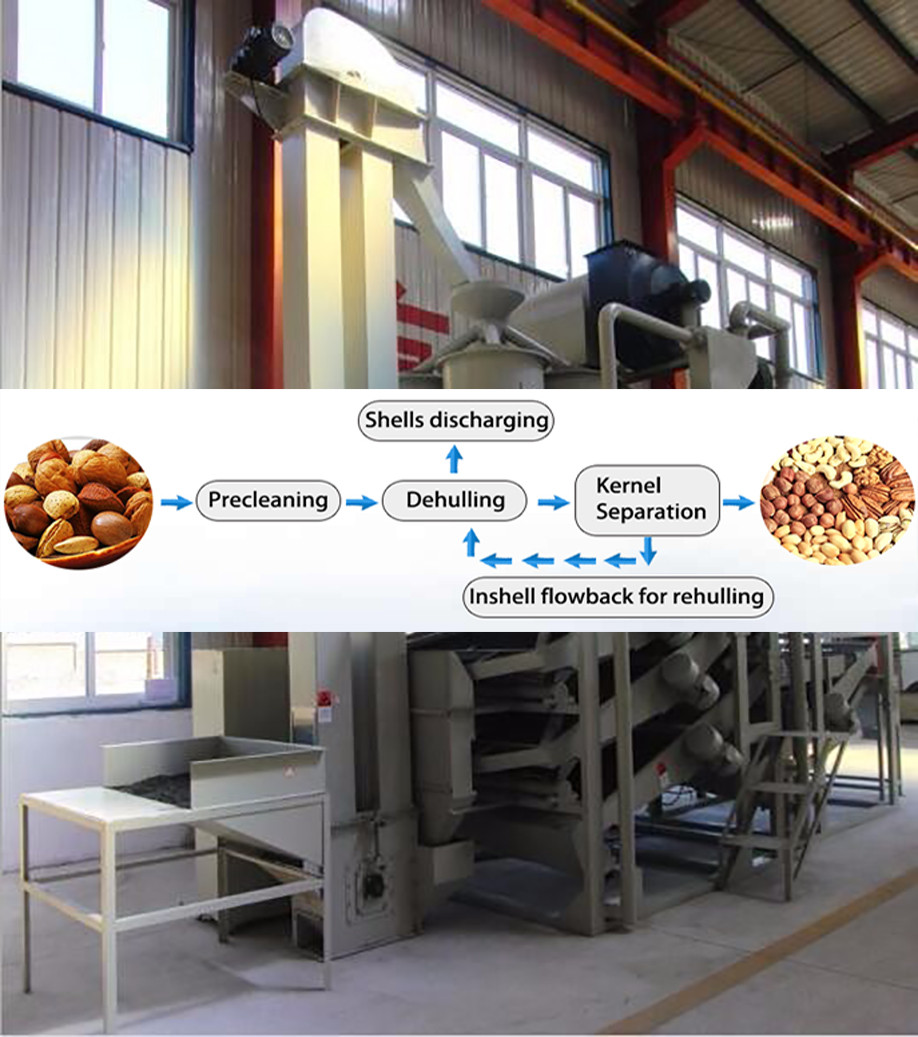

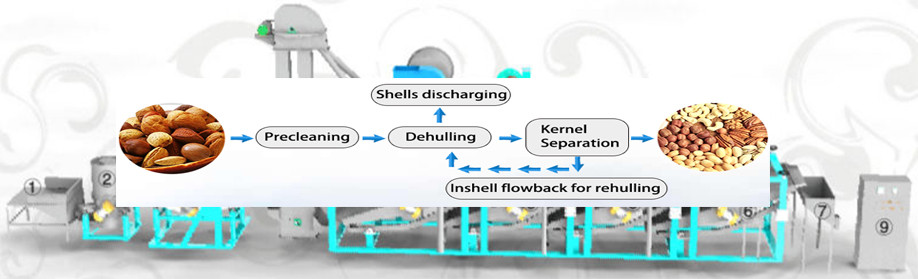

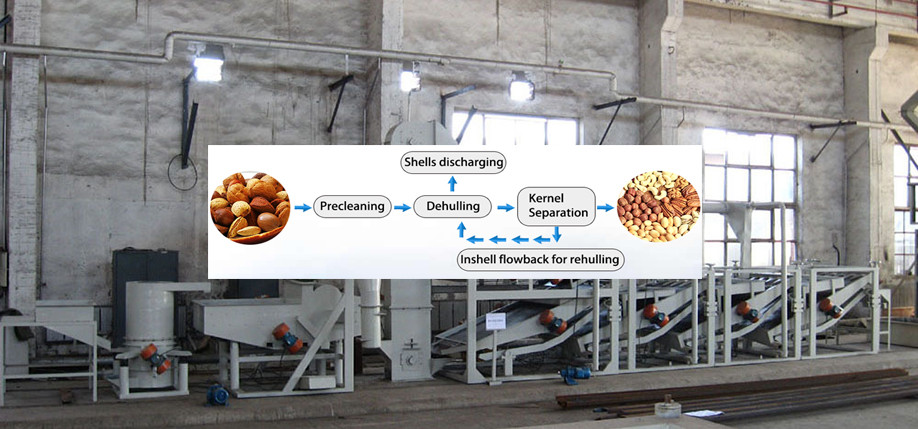

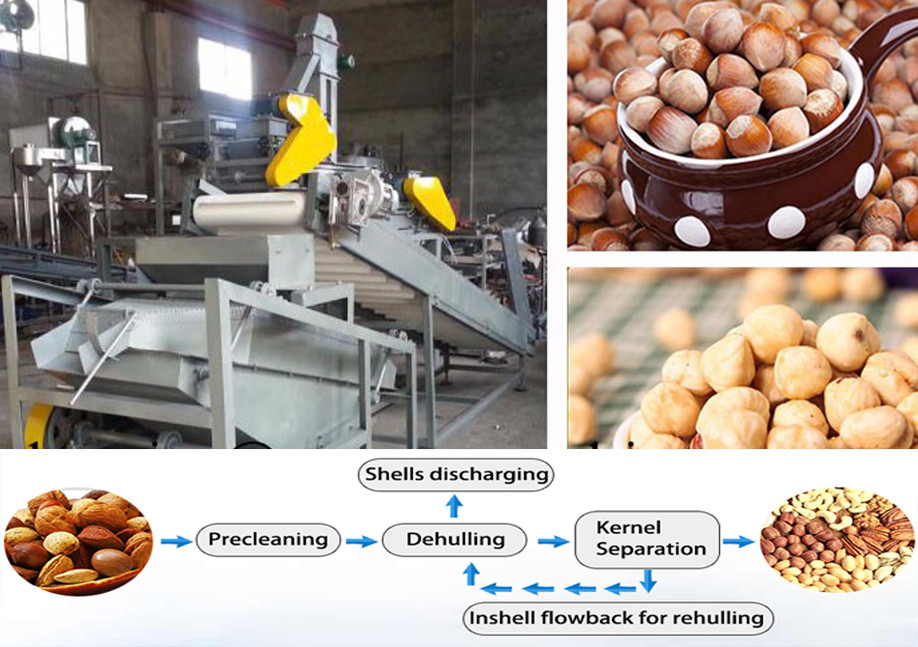

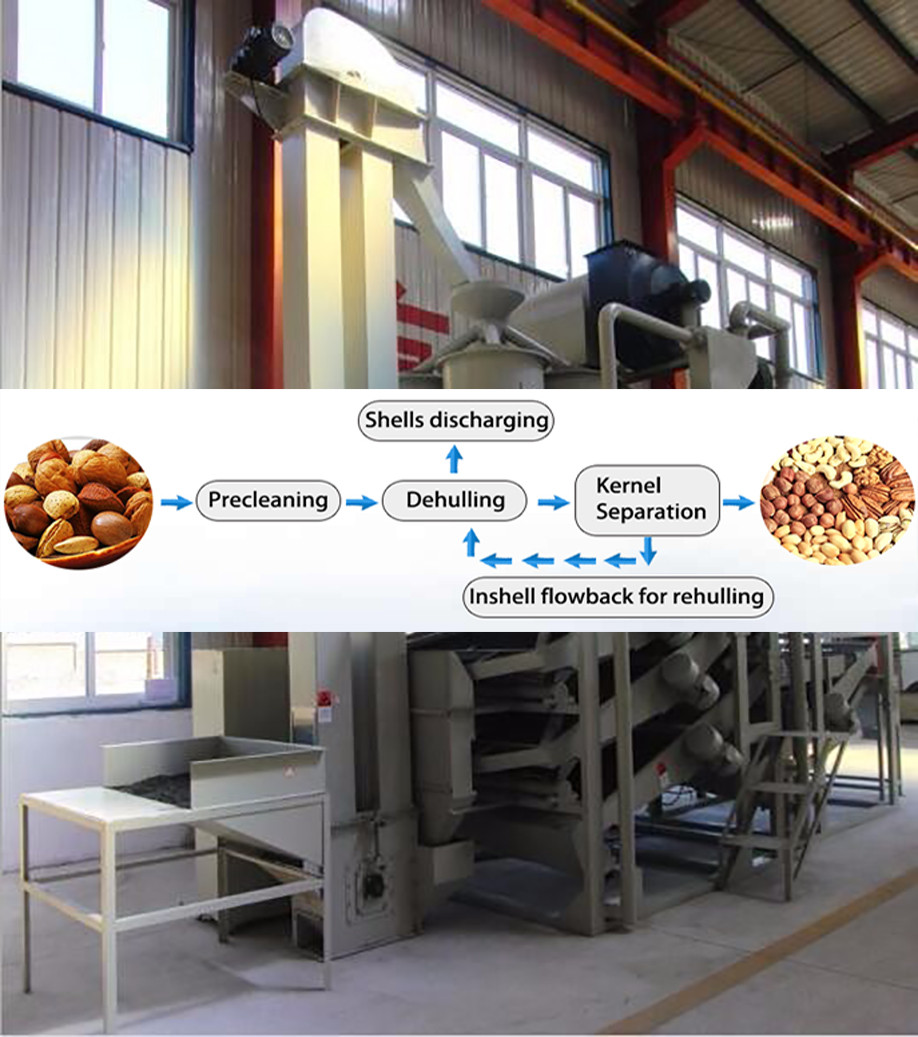

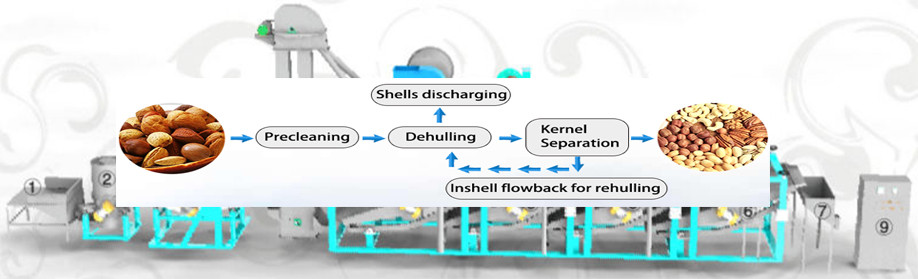

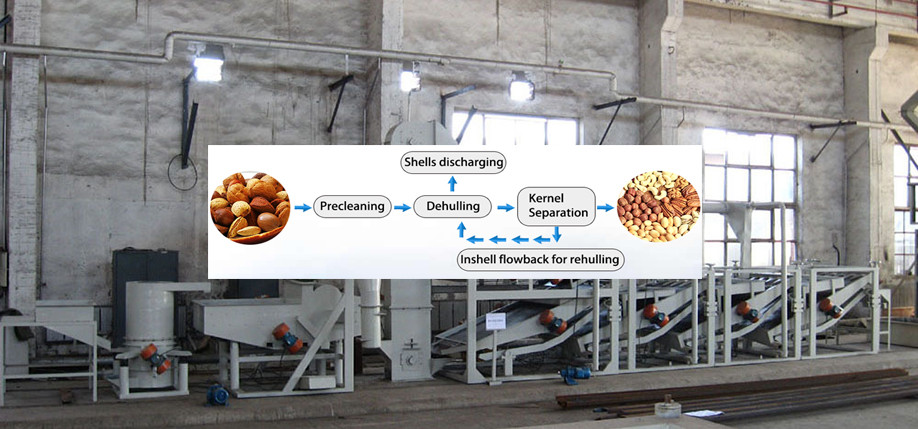

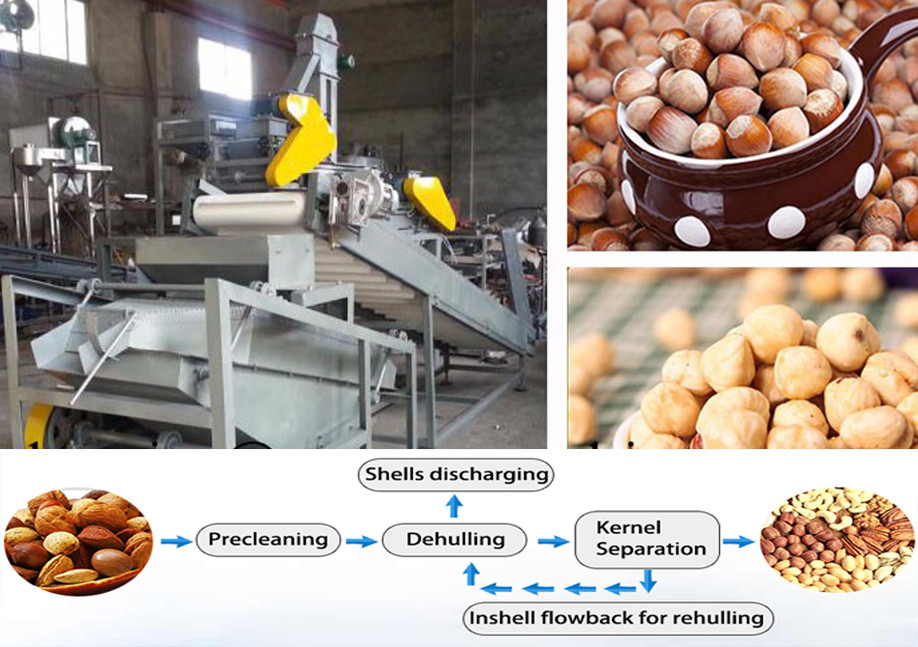

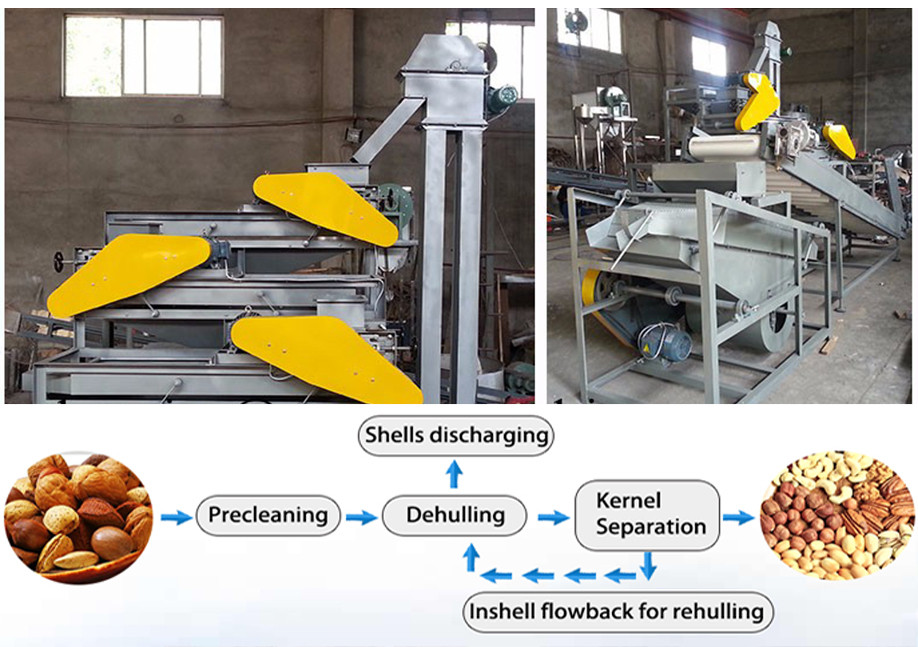

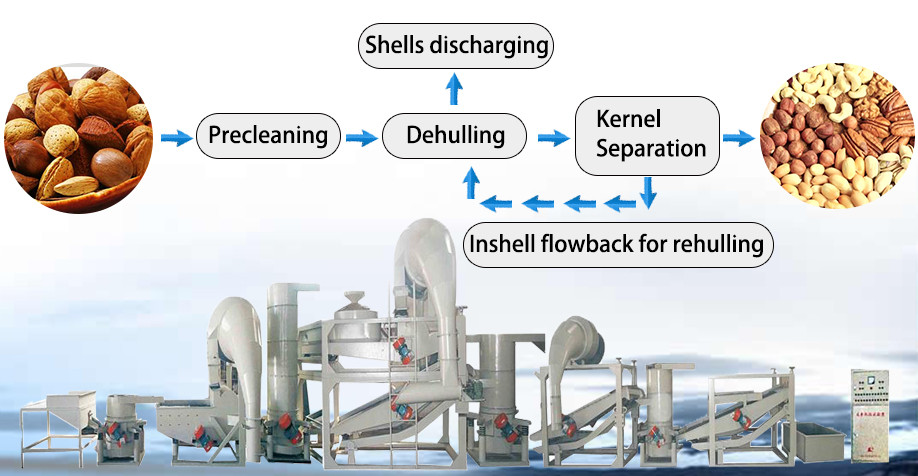

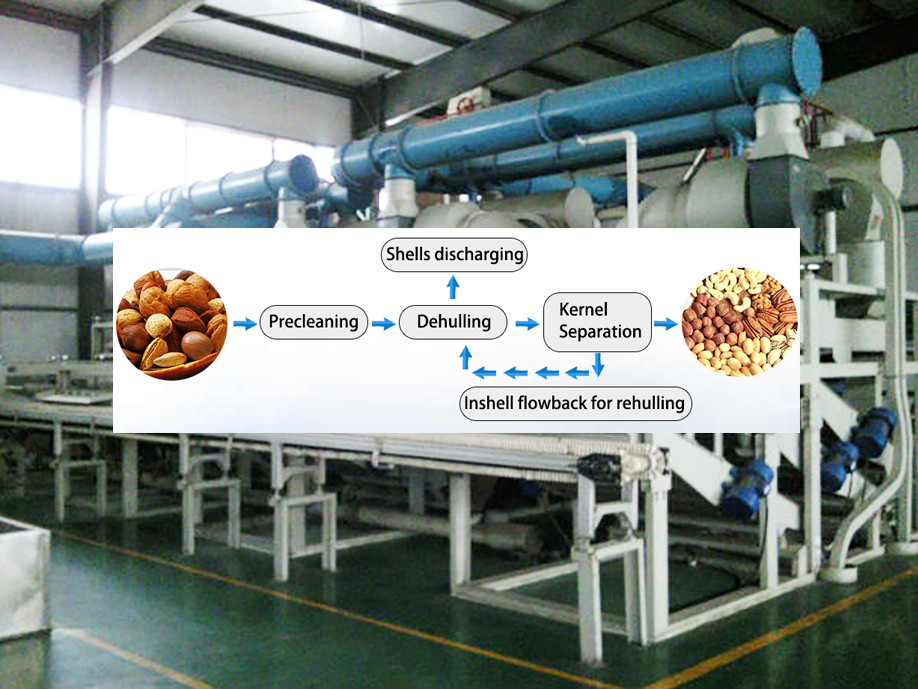

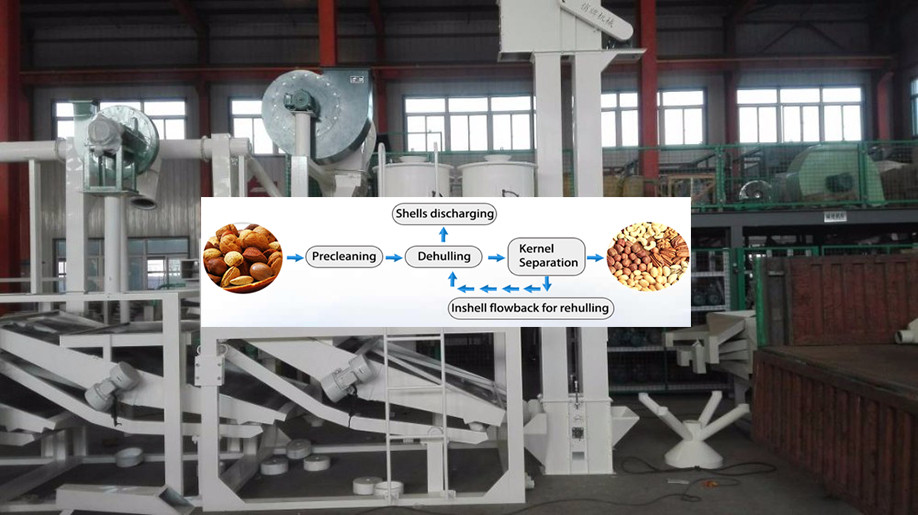

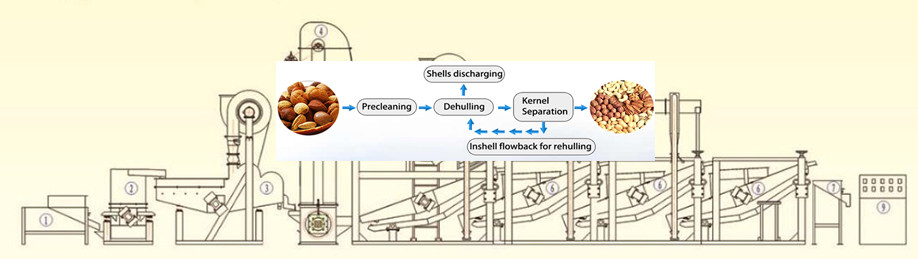

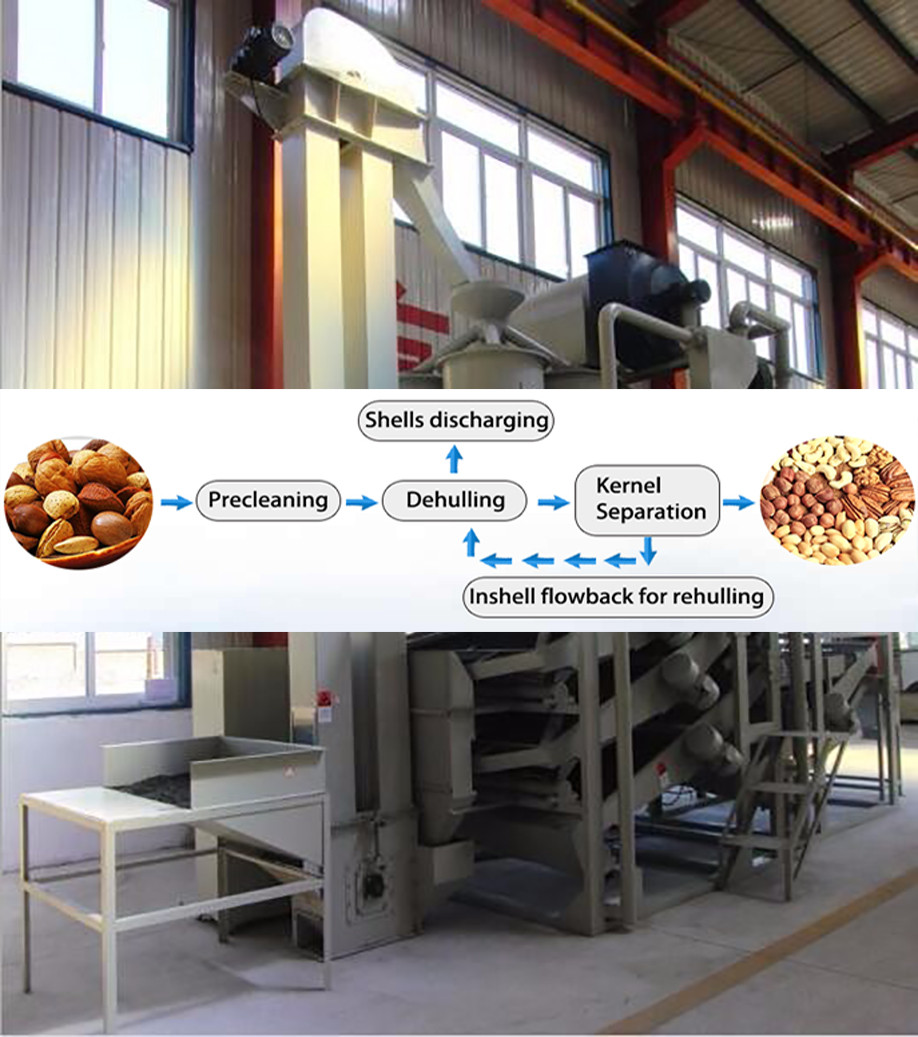

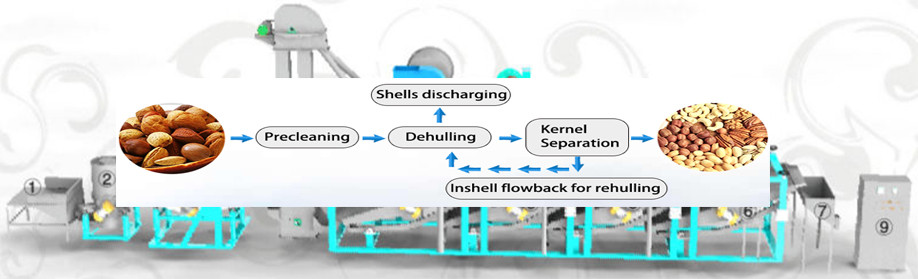

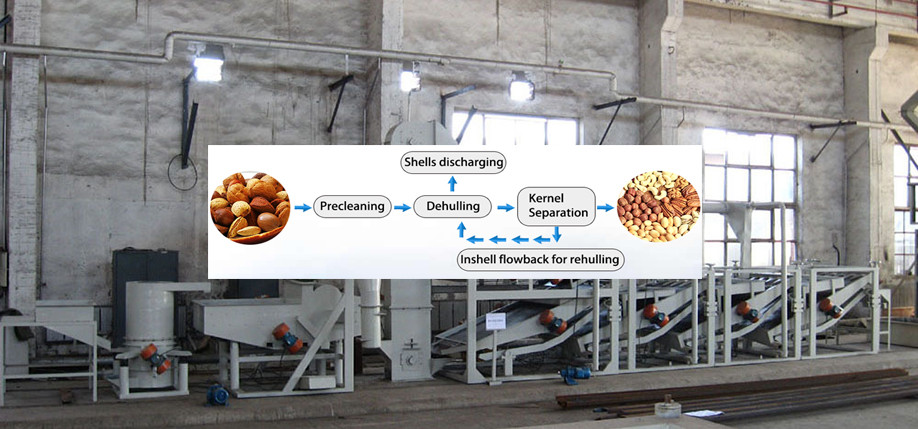

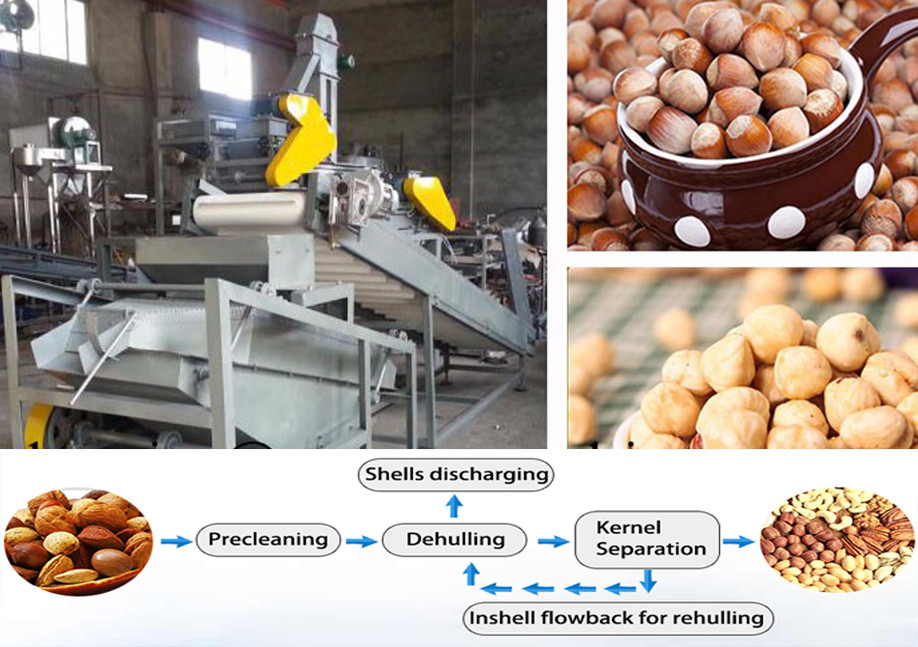

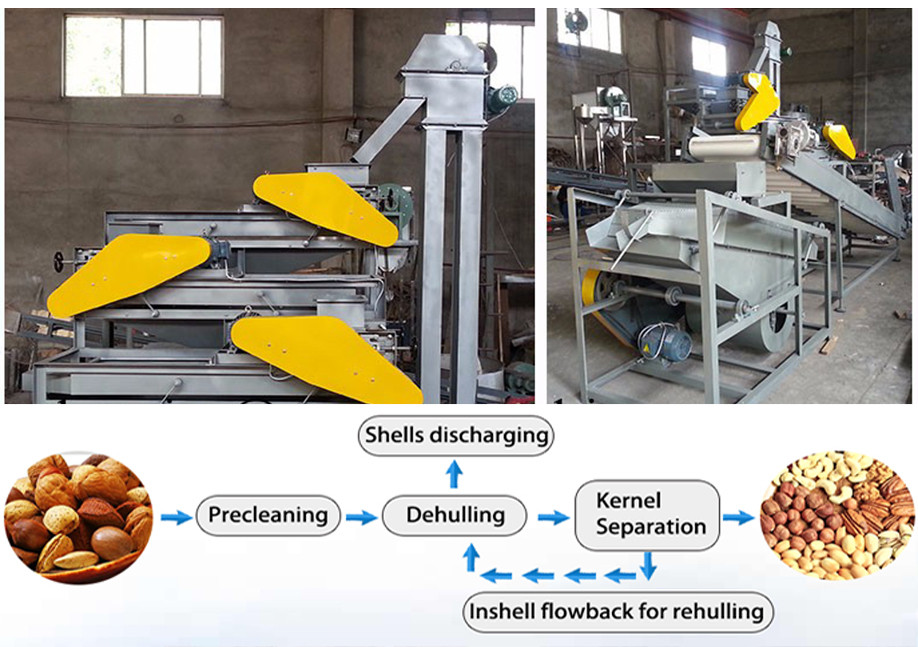

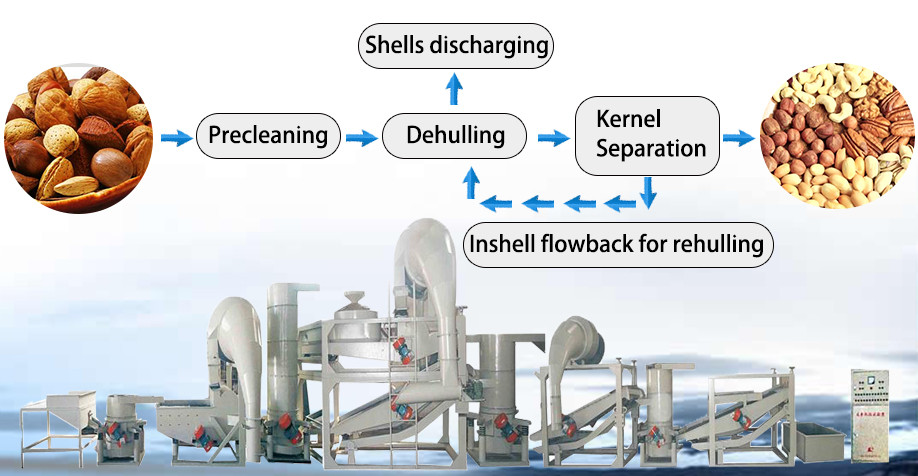

Photos of small wheat flour mill

Final product

Contact information:

Contact :Larry He

Skype:Larry.he3

QQ:2746542104

Tel:86-18939526905

Fax:0086-371-53392380

Email:larry@aslanjixie.

com

Any questions if you have, please do not hesitate to tell us.

Any questions if you have, please do not hesitate to tell us.

Your satisfaction is what we are always struggling for!